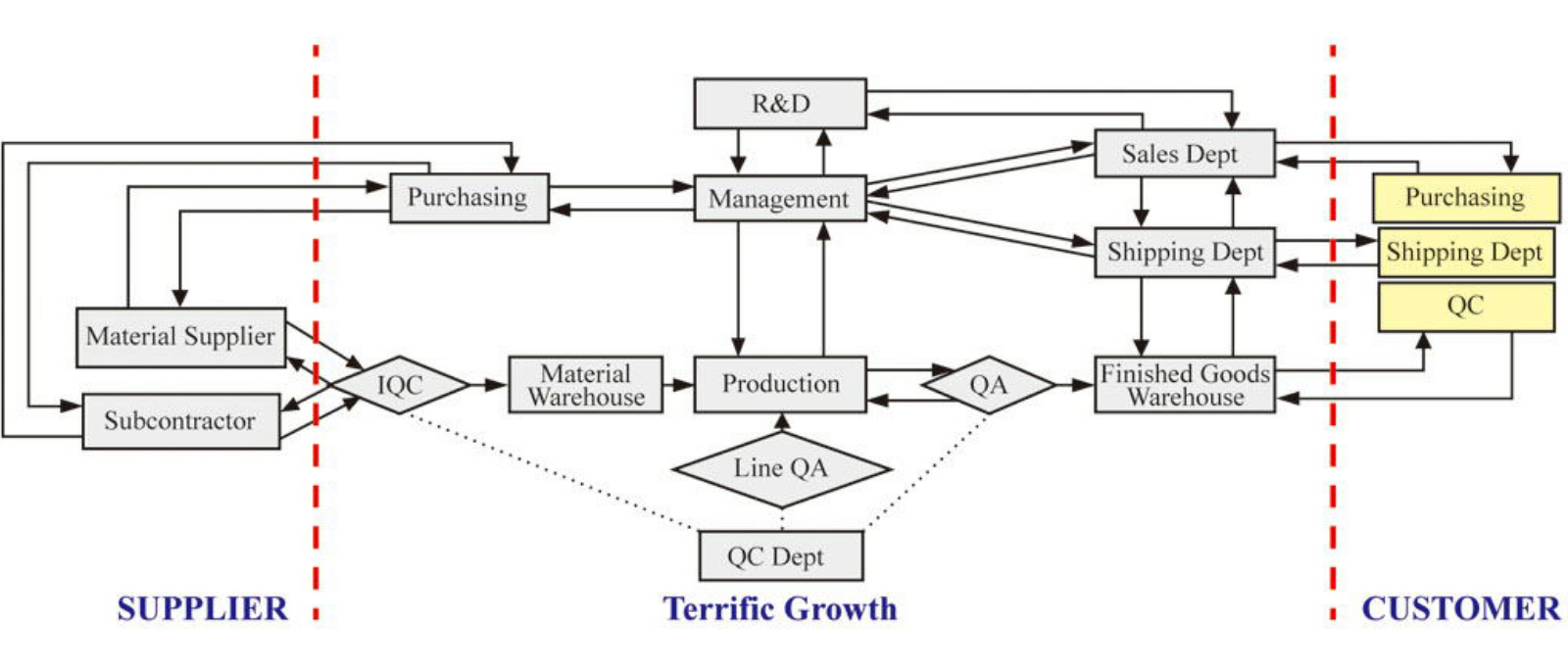

QC PROCESS

PANDAVIEW believes that in addition to ensuring the high quality of raw materials, the final product quality can only be guaranteed if it is strictly controlled during the production process. So we strictly control each step of the production process, including the inner diameter, wall thickness, outer diameter, hardness, tensile strength, peel strength, burst pressure, enduring pressure, UV resistance testing of the tube to prevent the product from aging easily.

The following are the main steps and methods of quality control in the production process of our company.

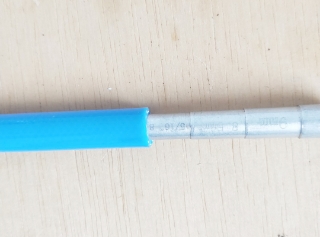

Inner size diameter measurement

Outer side diameter measurement

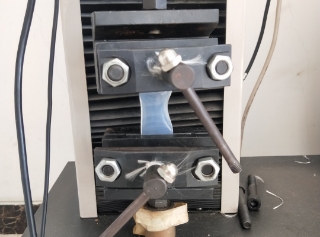

Peel strength testing

Tensile testing

Testing under cold temperature

Some customers, especially those in Canada, Russia and other countries, have reported that some suppliers' products are easy to harden or even crack in winter. For this reason, our company has also done relevant tests to ensure that the products are still soft enough at extremely low temperatures.Of course, some very hot countries, such as UAE, or African countries need harder products.

Products hardness

Air hose bursting pressure testing

B.P. testing machine

Discharged hose bursting pressure testing

Big size Discharged hose B.P. testing

Anti-UV testing

Discharged hoses are usually tested not only for instantaneous burst pressure, but also for permanent pressure.

Our test equipment will simulate rain, wind, high temperature and sunlight in summer in the natural environment, but the ultraviolet rays in the equipment are dozens of times that of sunlight in the natural environment. Generally speaking, 24 hours of ultraviolet irradiation in this equipment is equivalent to one year's equivalent in the natural environment, and our company generally tests continuously for 48 hours.